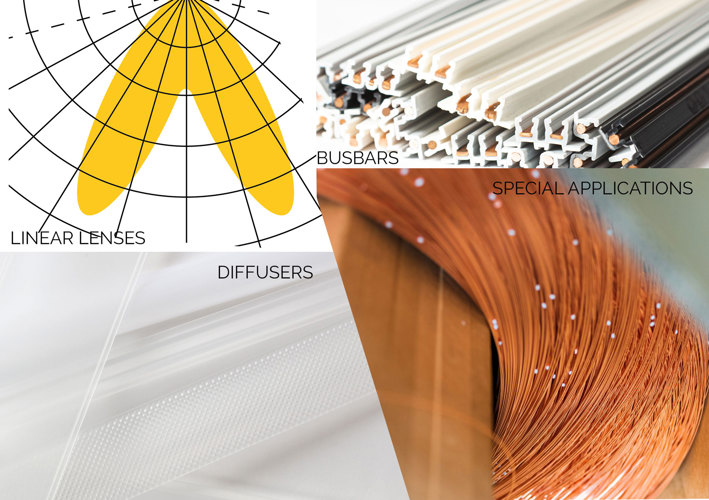

Four Lighting Solutions We Make Better

We design and manufacture innovative profiles for linear lighting and track lighting systems. Read on to find out how we make four lighting solutions the best they can be.

Busbars

Busbars are used in track lighting to conduct current to luminaries and insulate the electricity from the track housing.

How do we make them better? As well as PVC busbars, we’ve also developed alternative PVC- and halogen-free busbars with UL94 V0 approval where low flammability is needed. All our busbars are available in different sizes, shapes, and with multiple conductors.

You can position them anywhere in luminaries. They’re easy to install and cables are not visible.

Diffusers, covers, and tubes

Diffusers hide LED hotspots in lighting applications and lower unified glare rating. Tubes and covers protect the LED light source.

We make them better by enhancing the material properties to improve impact strength and flame retardancy. Material selection and surface modification lead to higher energy efficiency of the luminaire, which leads to better value for money.

Our diffusers, covers, and tubes can be used for various linear lighting applications.

Linear lenses

Linear lens profiles create special lighting patterns. They’re very efficient and protect the light source at the same time. We extrude them from PMMA or PC, giving them superior strength and fire retardancy. They’re easy to assemble - no screws. Lens types can be produced in various lengths compared to injection-moulded lenses.

Special applications

Sometimes you need something special. We can combine different profile features into a single product by co/tri/quad-extrusion as well as providing a special finish for profiles.

Examples of special applications include adding an absorber layer to a profile giving it superior UV resistance. We also enhanced sealing lips to improve their IP classification. We can machine profiles to minimise labour during assembly phases.

Special applications by their very nature have many design options. We make sure they’re always easy to assemble. They have a long lifetime in the special environments they’re designed for. This leads to a lower total cost of production cost.

We’ll be exhibiting at Light + Building in Frankfurt from 2-6 October. Hall 8.0, Booth F11.

About Primo

Headquartered in Copenhagen, Denmark, Primo A/S operates 12 sales and production sites across Europe, China and the USA. Founded in 1959 by the Grunnet family, Primo specializes in custom-designed plastic profile solutions. The company employs around 1000 people and reported a turnover of 180 million EUR as of December 31, 2024.