The age of PVC-free medical infusion tubes is coming

Primo Medico has finalized testing a new ground-breaking system for non-PVC medical tubing which will eliminate the risk of PVC interacting with patients’ body fluids. The system, which could have a huge impact on appliances, products, and procedures in many medical areas, will be showcased at the upcoming Compamed Trade Fair 2019 in Düsseldorf.

The successful development of the new PVC-free tubes is a result of a joint venture between Primo Medico and the supplier of medical plastic raw material, MELITEK A/S. MELITEK has developed a new TPE compound which is then used to produce layered tubes at Primo Medico. The laboratory technicians at PRIMO MEDICO have refined the processing of the TPE compound to utilize the best properties of the material.

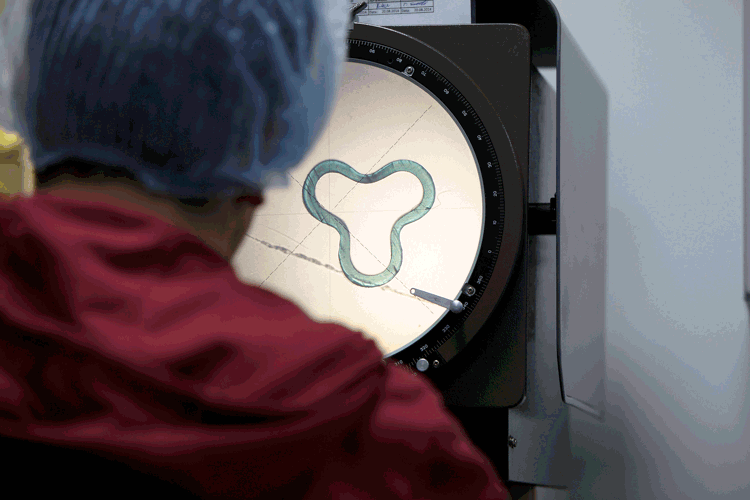

The result is a 2 or 3 layered tube based on TPE which can be used for medical devices. This is ground-breaking since PVC and especially phthalates can be problematic in medical products. Today, medical tubing relies on the flexibility of PVC to build secure and tight connections between tubes and other elastomers. Until now, soft PVC has been necessary to ensure that connections are tight and do not leak.

“Tests have yielded great results in terms of functional use of the tubes, and in addition the PVC-free tubes can be connected using the cyclohexanol connection method in the same way that PVC tubes are connected today,” says Daniel Kulwas, International Business Development Manager at Primo Medico.

In addition to being very cost-effective due to the low density of the materials used, the PVC-free tubes also offer a greener alternative to the soft PVC medical tubes for potential business partners:

“The new tubes will be an attractive alternative, not only for financial but also environmental reasons. PRIMO MEDICO and MELITEK A/S have together developed a solution to a long-standing problem for manufacturers of soft PVC medical devices as well as the medical sector which today relies heavily on PVC-based medical tubing applications. It is now entirely possible that we can replace these soft PVC products while maintaining our assembly processes and even improving functional properties,” Daniel Kulwas says.

Another benefit is that the PVC-substitute Polyolefin used in the new process is chemically stable.

“This means that we no longer risk that phthalates interact with intravenously dosed medication and that is a gamechanger. Both hospitals and OEMs have been looking for a solution to this problem for a long time,” says Business Director at MELITEK A/S, Jesper Laursen.

The tubes are sterilized by all available methods except steam. Tubes dedicated for steam sterilization are still in the testing phase.

Primo Medico estimates that the new medical tubing applications will be ready to be marketed in 2020.

Primo Medico and MELITEK A/S can be found at a shared exhibition (Stand L09, Hall 8B) at the Compamed Trade Fair for Technology and Medical Devices in Düsseldorf, November 18-21, 2019.

About Primo

Headquartered in Copenhagen, Denmark, Primo A/S operates 12 sales and production sites across Europe, China and the USA. Founded in 1959 by the Grunnet family, Primo specializes in custom-designed plastic profile solutions. The company employs around 1000 people and reported a turnover of 180 million EUR as of December 31, 2024.